|

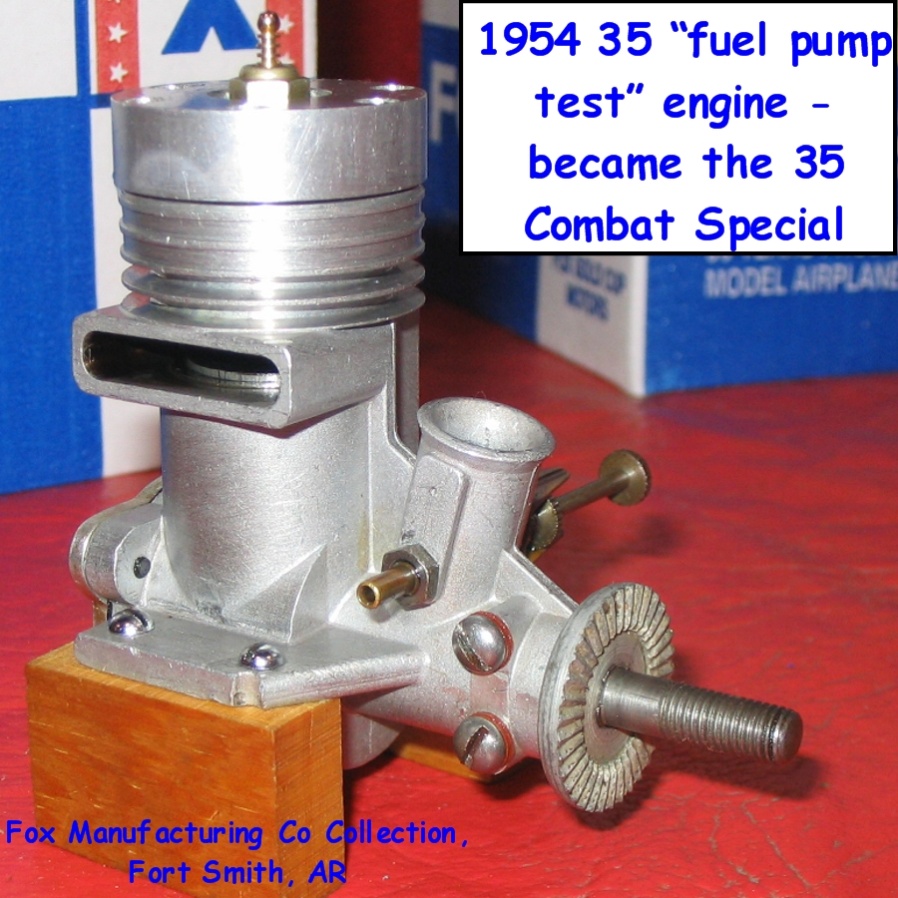

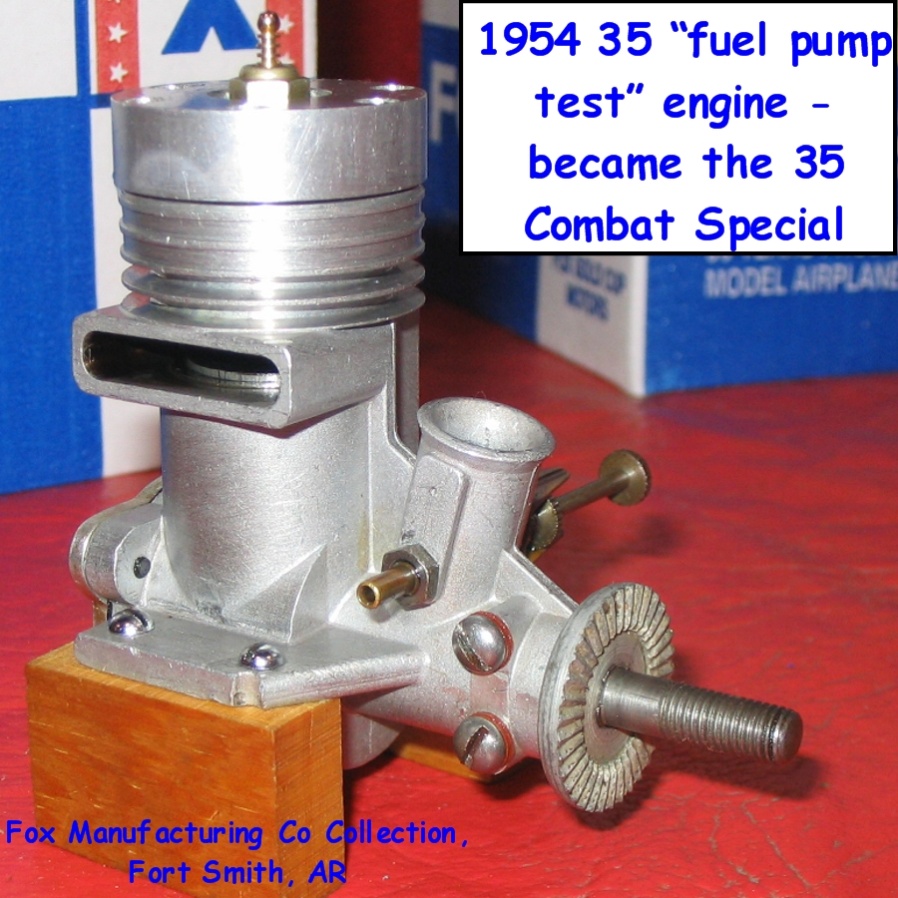

In his autobiography, Duke Fox mentioned around 1957 he wanted to develop

an engine for use in Combat, stronger than the Stunt 35. He turned to

an experimental engine designed in 1954. This engine was used to develop

a fuel pump built into the crankshaft. The fuel pump wasn’t successful,

but the engine was quite a strong runner. This engine was the basis of

the original Fox Combat Special. Then, low and behold, Charlie Thacker

(Fox Manufacturing Co.) found this experimental engine in the factory

and had it up at Toledo in 2004 where he graciously let me photograph

it.

This engine now resides in the MECOA Museum.

|

|

| So in 1957, the 35 Combat Special (43) was introduced. It had a large

½” dia. crankshaft, 4 bolt rear cover with a spigot for a pressure

tap, bosses between the cylinder fins to stiffen the case, a tall venturi

with a removable steel insert, and the “spade tipped” NVA. This

tip was supposed to stabilize the end of the needle and prevent fuel foaming.

Of course, the engine was timed for power and handling. |

|

| Building on the strength and success of this engine, the first 29X (48)

came out in 1958. Like the Stunt 29, the 29X was a 35 with a .738 bore.

Also, the “35” cast on the bypass was spot faced off and a cylinder

head with narrow machined slots was used. The spot face and thin slots became

the usual way to tell a 29 for years to come. |

|

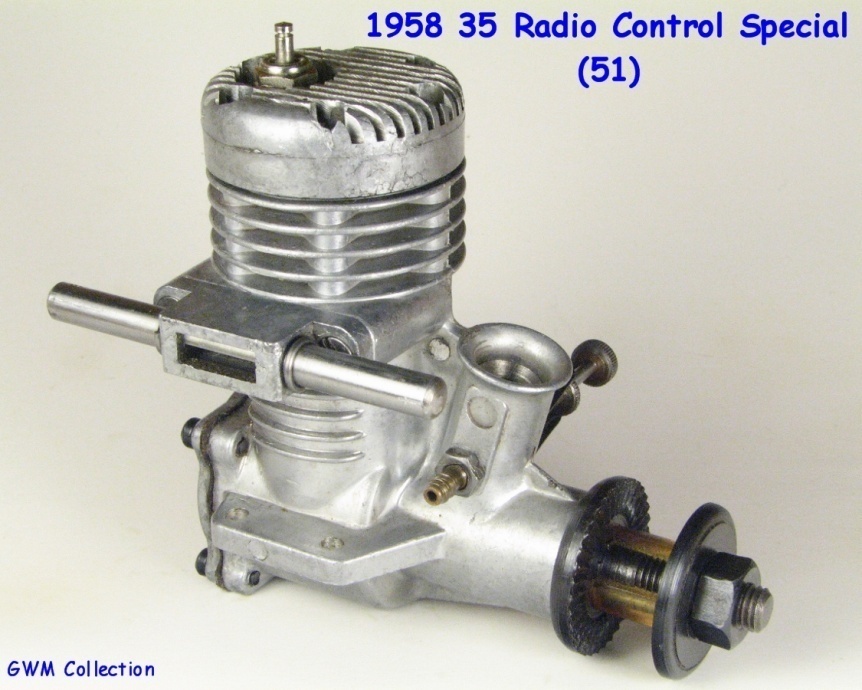

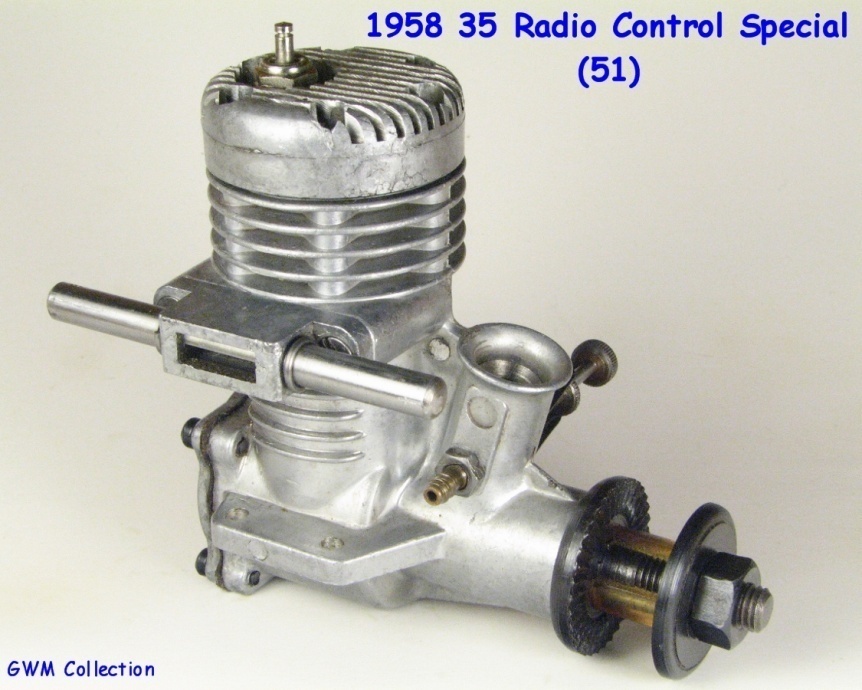

| 1958 saw the sale of the 35 Radio Control Special (51). This was the Combat

Special with cylinder timing from the Stunt 35 and a rotary exhaust valve

as was used on the 1957 19 RC Special (38). The most striking feature of

this engine was the cylinder head with the thin slots like the 29X, but

with the glow plug offset far to the back of the head. You’ll see ads

for this engine with a venturi clapper (choke) on the end of the rotary

valve shaft, but this one of Duke’s airbrush ads; the engine didn’t

come with the clapper. Internally, there was an oil groove cut into the

crankshaft bushing, absent on the CS. |

|

| All of the preceding engines had a round bottom on the front

of the crankcase; the next engines have “lugged” cases. In 1960

the case dies were changed to add lugs to front of the case. This allowed

the case to be used as the basis for the radically new 1960 Combat Special

Series III (59). This engine had a crankshaft that ran in front and rear

needle bearings set in a removable case front. The easily recognizable huge

intake showed up on the Series III. Internally, the port in the crankshaft

matched the intake and the liner had the “picture window” intake

port (from the 1950 29 Racing Special”). The rear cover came with a

pressure tap installed. |

|

The 1960 Rocket 35 (58) used the lugged case with a bronze bushed, fixed

front end. The Rockets, introduced in 1959, were Fox’s low priced

answer to the inexpensive McCoy 35s and even had a red head.

New Info from Randy:

The first release of the Rocket 35 did not have "ROCKET" and

the Rocket engraved on the bypass. Head was plain die cast, not painted,

and no wrist pin access hole was drilled in the rear of the case. Click

for manual

From the MECOA museum.

|

|

| By 1961, Fox realized the case was too weak to stand up to combat use;

the case walls were thickened .030 to .100 making the bottom of the case

.060 wider. Up to now, all the 35s had the same mounting hole pattern. In

1962, the dies were changed again and the case ended up with the bolt pattern

increased from 1 ½” to 1 5/8”. This was the case used on

the 1962 Combat Special Series III (74). This pattern has been used on all

the 35s and 36s since, except for the Stunt 35. |

|

|

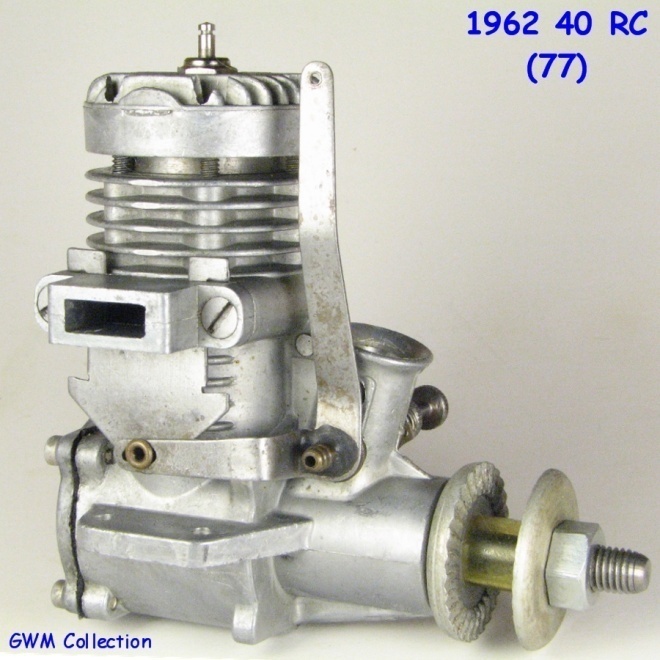

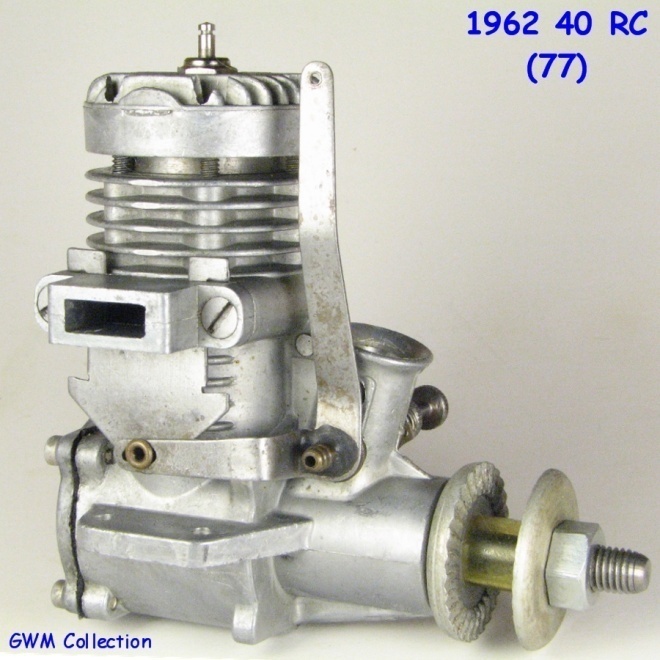

Another one of my favorite Foxes was the 1962 40 RC (77). By stroking

the 35, Fox ended up with a 40 (.800 x .790 B&S). The 40s are easy

to spot since they had a liner lip .090 thicker than the 35’s, producing

a pronounced gap between the head and the case. The RC engine had a rotating

throttle plate NVA coupled to the incredible vertically stroking “Guillotine”

exhaust valve. Fox sure had some unique design features. They remind me

of the dreamed up hints and kinks that used to be sketched up in the model

mags, except Fox really built some of them!

|

|

| 1962 also saw the introduction of one of the famous 35X. Fox took the

CS Series III and produced a one-piece case. It still used the CS internals

including the twin needle bearings. The first advertisement referred to

it as the 35 “Blue Ribbon” (75), but subsequent ads called it

the 35X. “35X” was cast on the bypass. It was supplied with an

aluminum venturi insert and no pressure tap on the rear cover. This allowed

it to be used as a sport engine; removing the insert and installing the

tap opened it up. To save money, this engine was sold in a blister pack

hang card; the purple card unfolded into the instructions. |

|

| Rat Racing was popular and in 1963 Fox sold the 40BB Rat Race (82); the

famous “Golden Rat”. Like other 40s, this was a stroked 35 and

has the wide gap between the head and case. It uses the Blue Ribbon/35X

case, but with the FRONT NEEDLE BEARING and a REAR BALL BEARING. The special

feature was the “gold” colored case, head, and rear cover. This

color was really a brass flash over a bright plating, reportedly applied

by GE (where Fox had done some work). A blue sticker proclaiming “FOX

40 BB RAT RACE” was applied over the cast “35X” on the bypass.

Of course the sticker fell off if the engine was used any amount and so

a lot of folks think they have a 35X. Some combat fliers actually did put

35 parts into the case, but a wide head to case gap will identify the 40.

The gold color also wore fast resulting in a chrome plated or polished look.

|

|

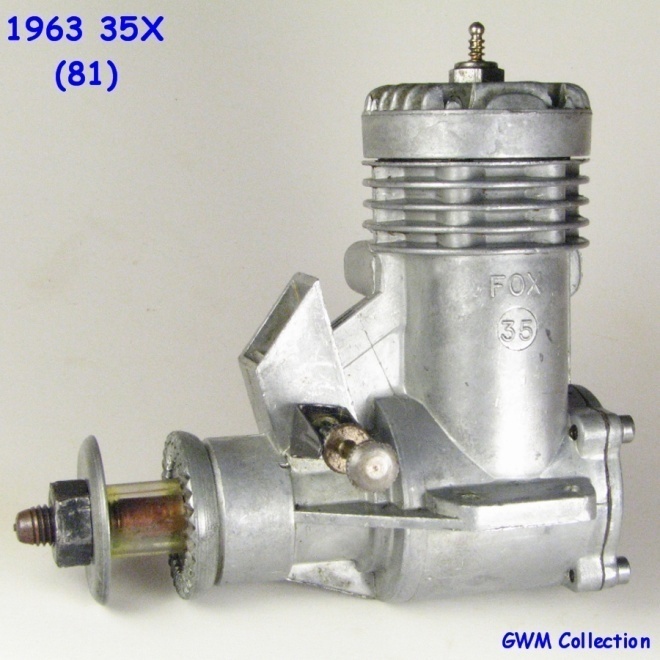

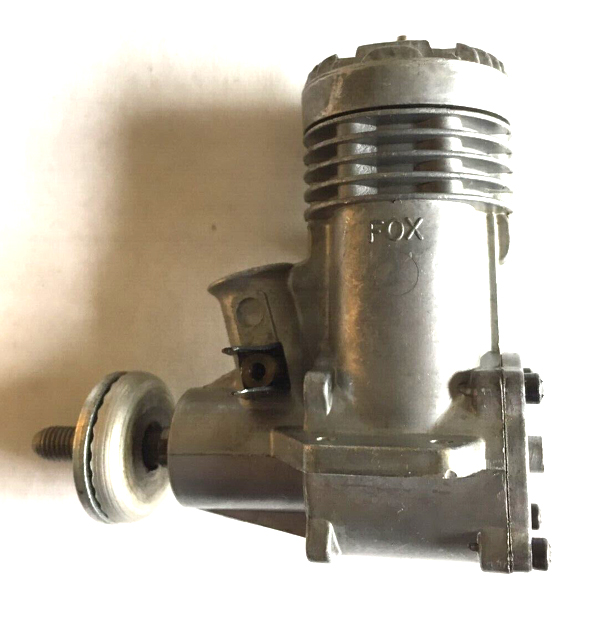

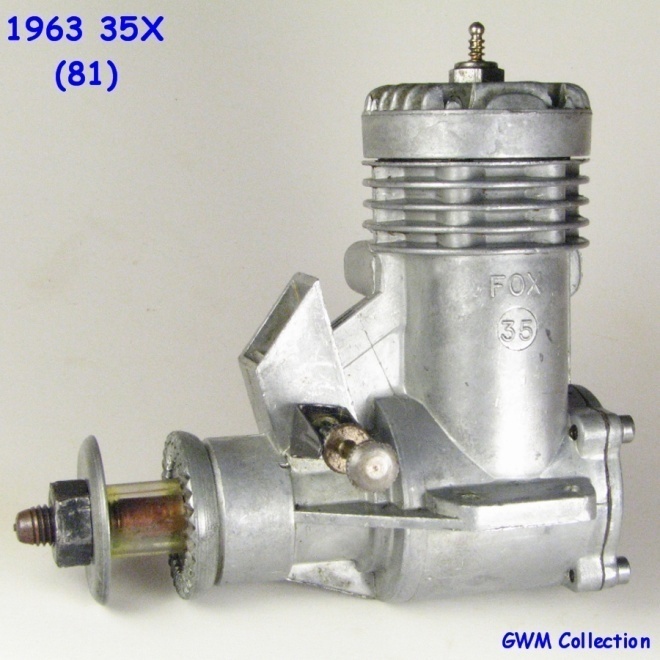

| The next 35X (81) came out in 1963. It looked much like the Blue Ribbon,

but had 3 reinforcing webs on the front of the crankcase. Behind the thrust

washer, the front needle bearing was missing and the shaft ran in the case

material. The rear needle bearing stayed. This proved to be an economical

and powerful engine. |

|

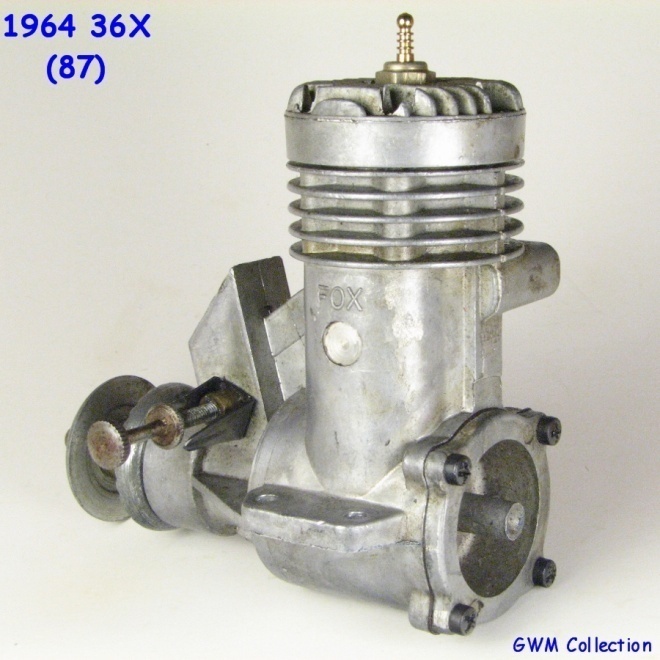

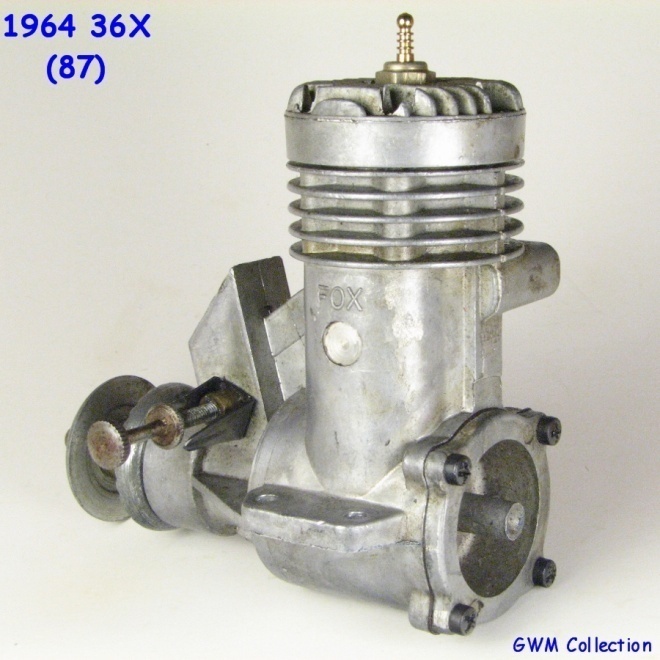

| The 35X crankshaft was weak around the wrist pin. Larry Scarinzi was working

with Fox to modify the engine for more power and strength enough to run

high nitro fuel (Fox Blast). The crankshaft web was strengthened and while

Fox was at it, he stroked the engine .015. The picture shows the difference

in the cranks. Now with an .800 x .715 B&S, in 1964 this engine became

the first .36X (87) taking full advantage of the displacement allowed by

the combat rules. From then on, all Fox .36s have used this .800 x .715

setup. A spacer was installed under the head to compensate for the increased

stroke. To keep from confusing the 36X with the 35X, the “35”

was spot faced off the bypass. This is the only Fox with the spot face that

IS NOT a 29. |

|

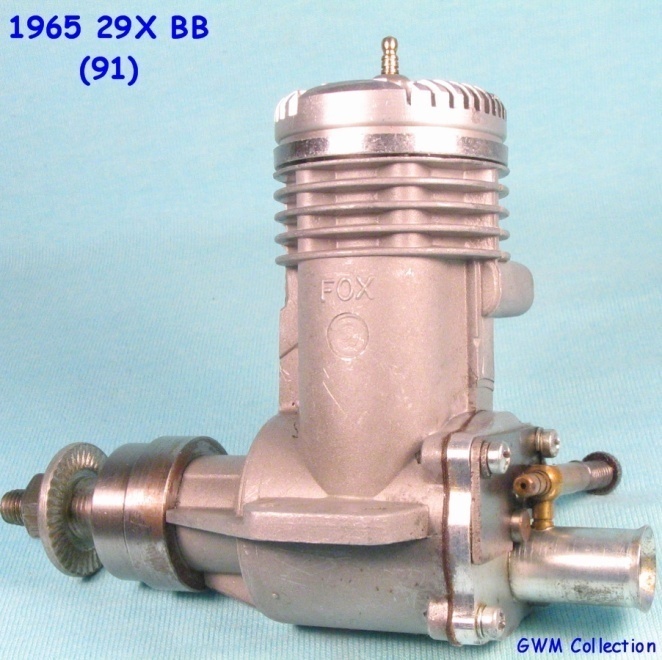

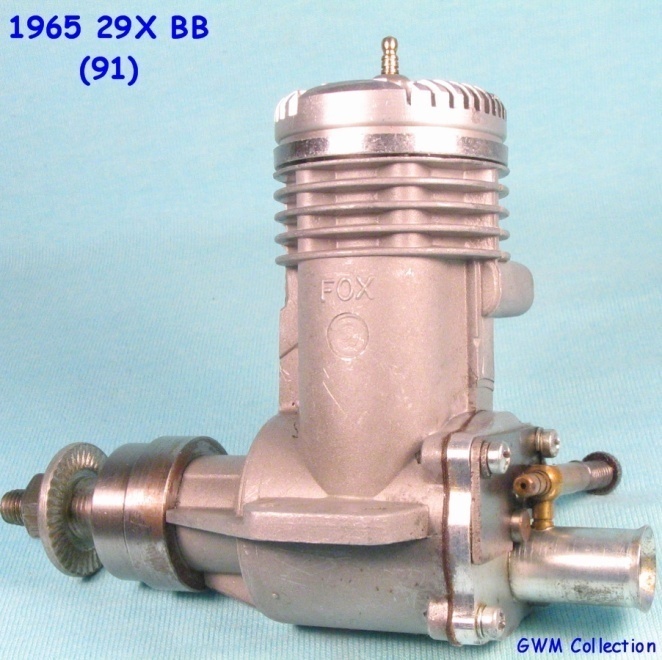

| A very special 29X was made in 1965; the 29X BB. It was based on the 35X

case, but used 2 ball bearings on the crankshaft and rear disc valve induction.

It had the narrow slot machined head and a grayish (maybe greenish) finish

on the case, sort of like a military aluminum ordinance finish. Up to now,

Fox could just change the bore size of a 35 to make a 29, but now the 36

engines had a .715 stoke. Fox had to start making special 29 crankshafts

with the old 35’s throw to maintain the 29’s .738 x .700 B&S.

The crankshaft webs were usually stamped with “29”. |

|

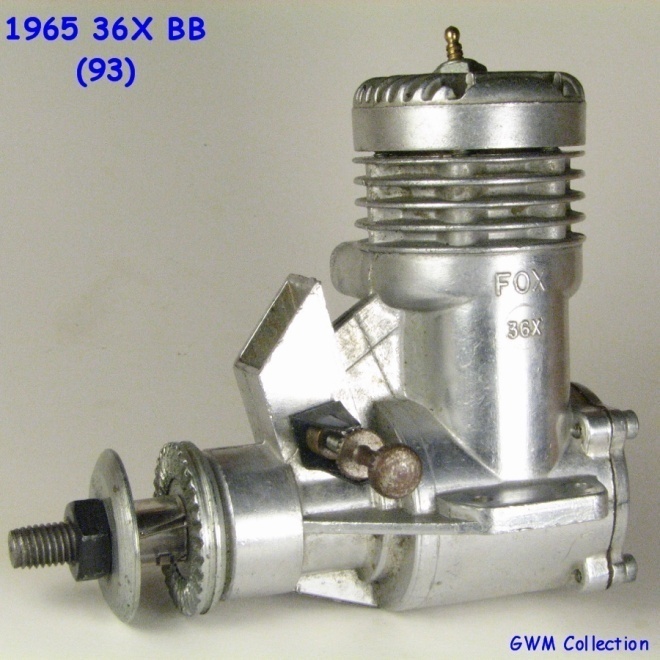

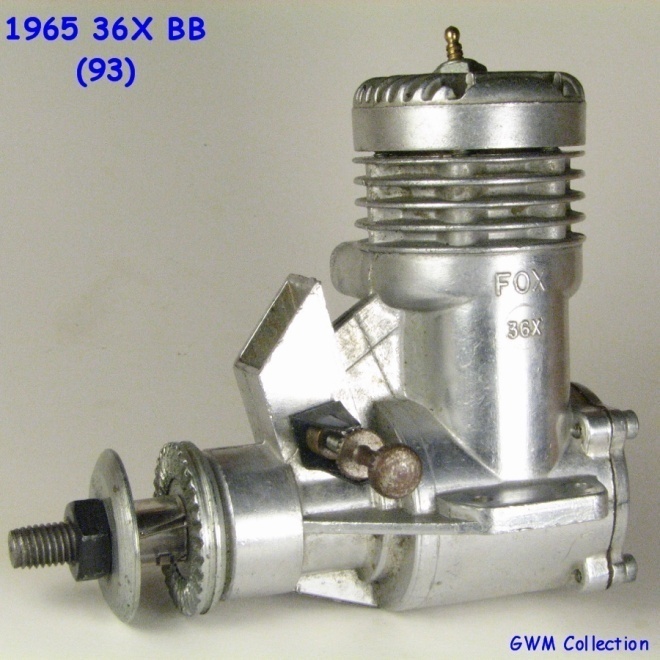

| The next major change was in 1965. A bulge bypass was incorporated into

the old case allowing more intake area. A slanted plug position was used

to allow fast glow plug changes in Combat matches without bashing your knuckles

on the wing’s LE. The first ads show the glow plug slanted to the bypass

instead of to the exhaust side. “36X” was cast on the bypass.

The regular 36X retained the front bushing, rear needle. A 36X BB “Custom

Fitted for Combat” (93) was sold which replaced the rear needle bearing

with a rear ball bearing, added a pressure tap in the rear cover, and a

polished bright finish. |

|

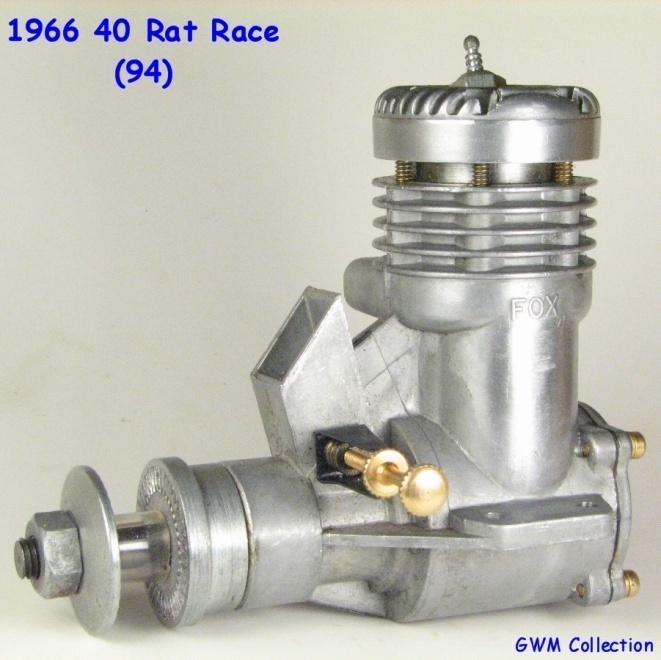

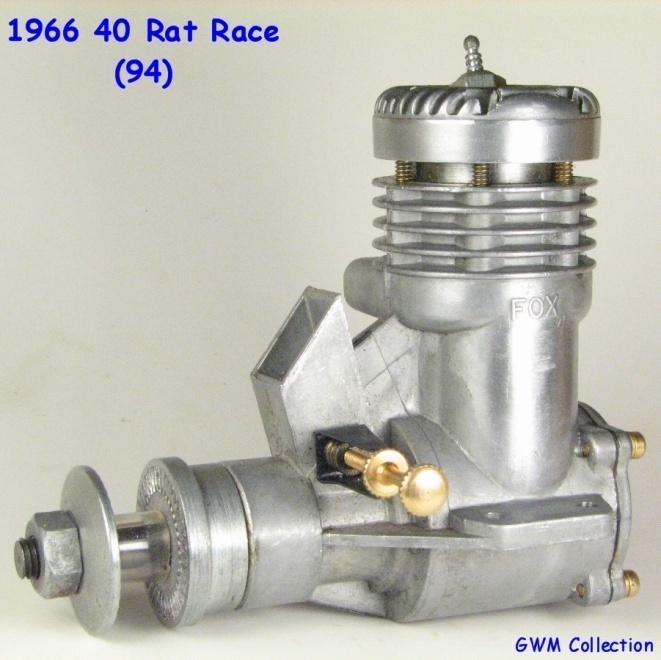

| A low production 40 Rat Race (94) was sold in 1966. It had the “36X”

ground off the bypass and used a needle bearing front, ball bearing rear

crankshaft and a rather heavy steel prop driver. |

|

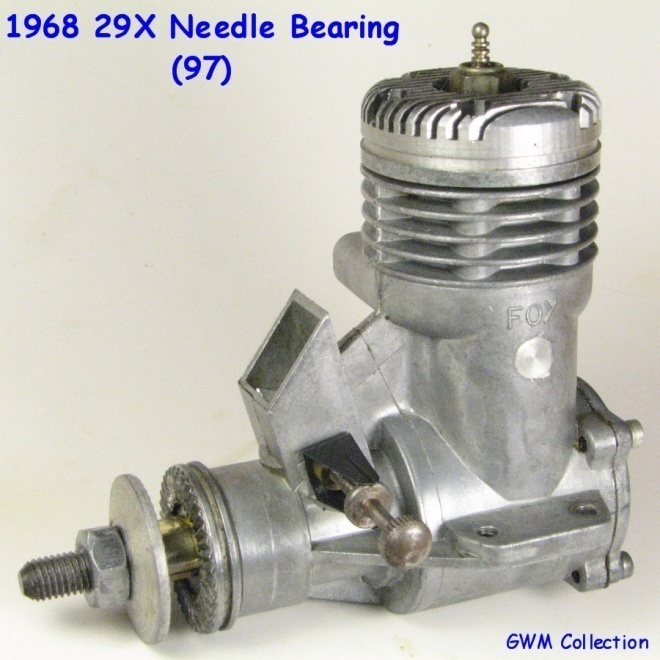

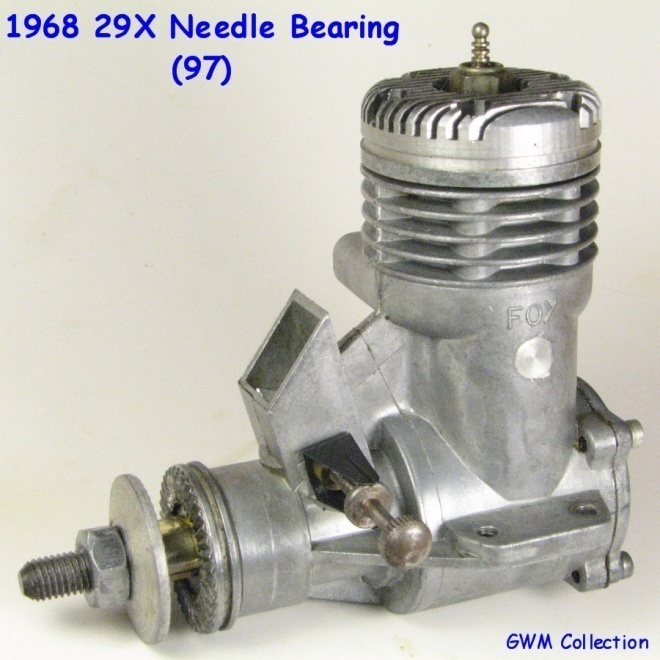

| The 29X Needle Bearing (97) came out in 1968. Basically a 36X with the

special .700 stroke crankshaft (stamped “29”), spot face on the

bypass (often with a very lightly stamped 29), and a cylinder head with

narrow slots, a central vertical glow plug, and a shallow groove around

the circumference. |

|

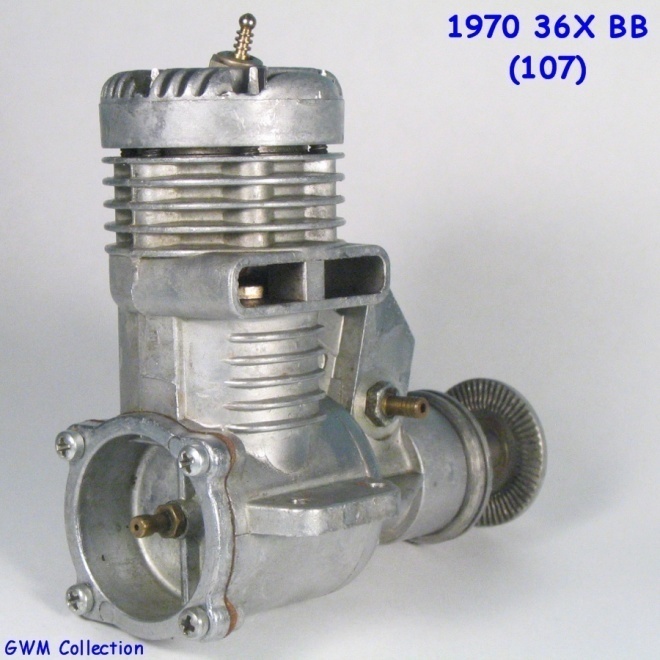

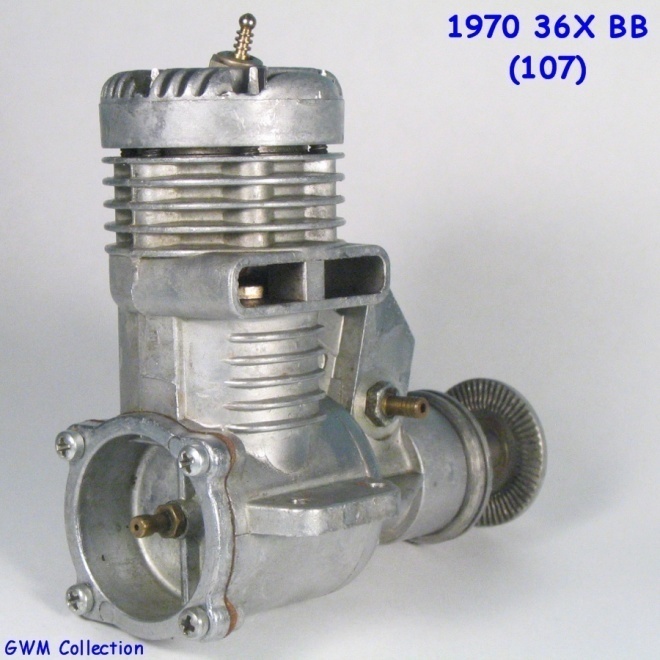

| The 1970 36Xs had a cast in exhaust web required for mounting the swinging

exhaust baffle on the RC versions. Another 36X BB (107) “Custom Fitted

for Combat” came out, much like the 1965 version, but with a “Stuffer”

rear cover and pressure tap. This rear cover was larger in diameter than

the original and reduced crankcase volume. The case on this engine wasn’t

polished like the first version. |

|

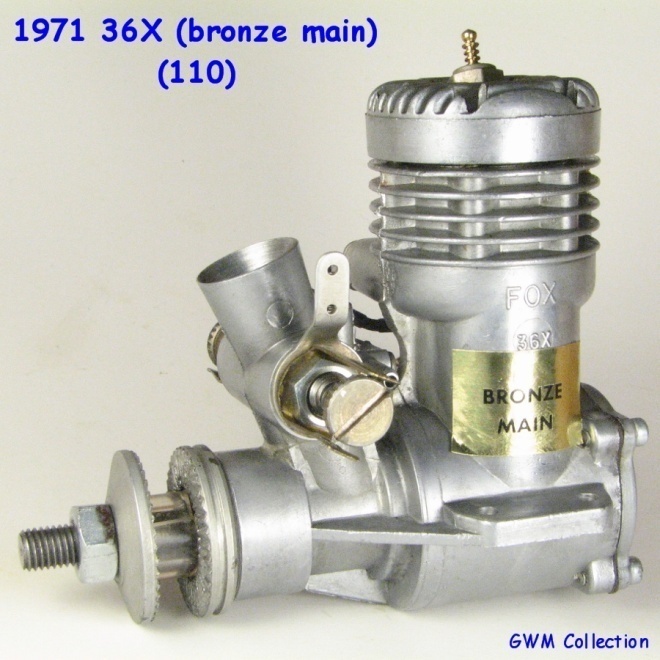

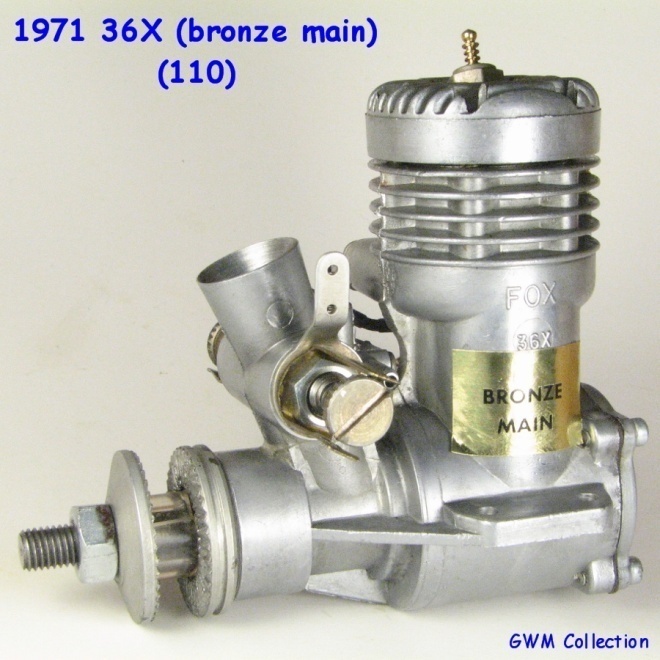

| There were special control line events like Profile Navy Carrier where

the engine could not use anti-friction bearings. In 1971 Fox produced both

throttled (110) and unthrottled 36X Bronze Main engines. They had a full

length bronze main bearing in place of the case material and rear needle

bearing. A “P” was stamped on top of the right mounting lug. A

gold sticker on the bypass and the box announced “Bronze Main”.

The bronze bearing can be easily seen behind the thrust washer. |

|

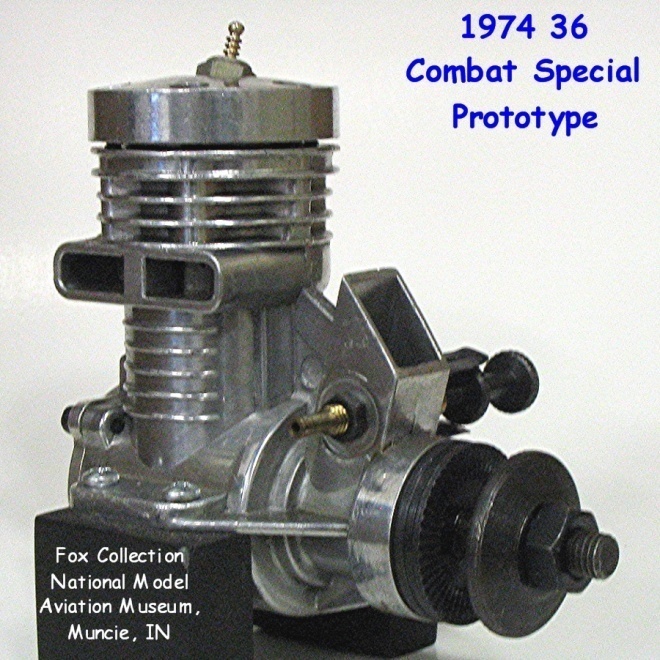

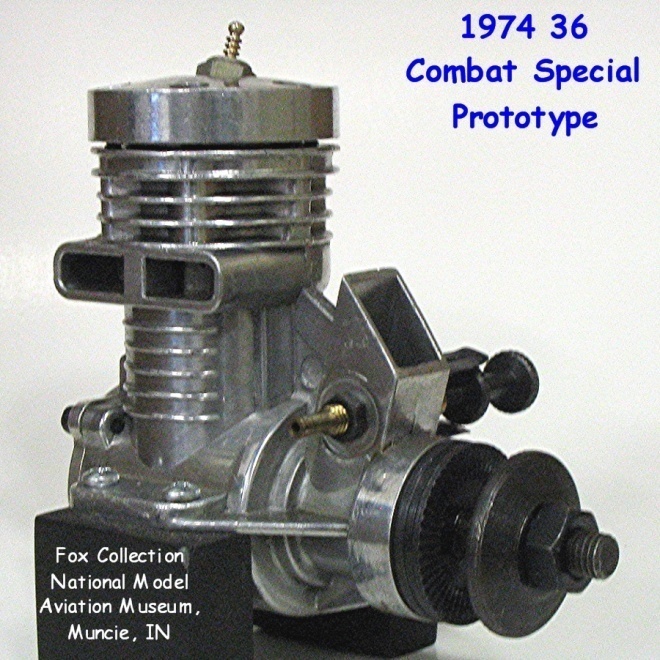

| The 1974 Fox catalog shows a 36X Combat Special (no number) with the web

in the exhaust, a heavy grooved thrust washer, a smooth finless head, and

the suction NVA from the 36Xs. I don’t think this version was ever

sold, but the prototype used for the catalog is in the collection of The

National Model Aviation Museum, Muncie, IN. |

|

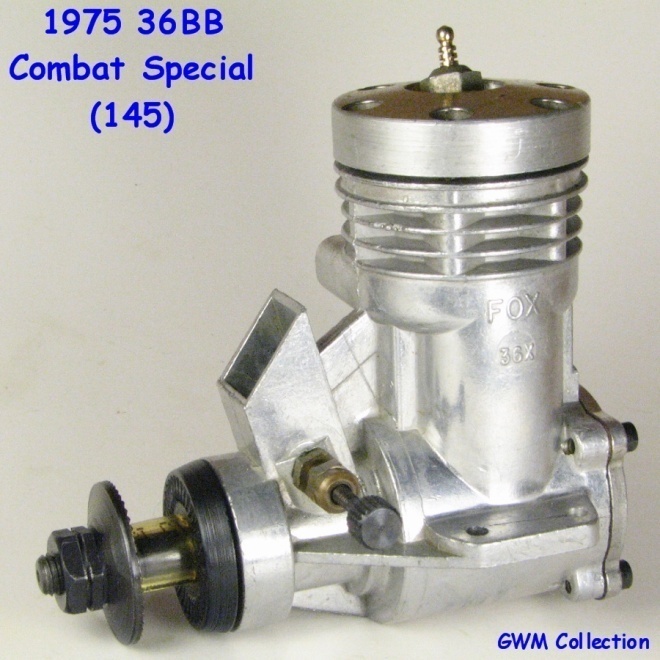

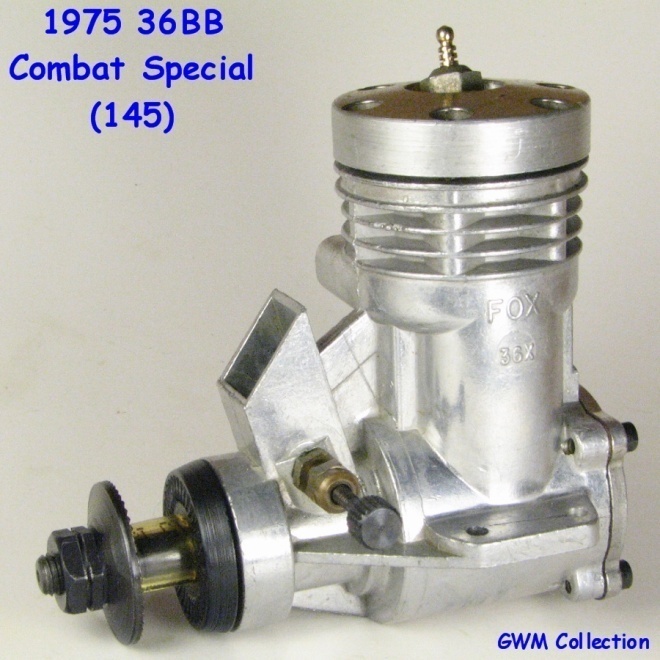

| The 1975 36X BB Combat Special (145) was produced. It also had the smooth

head with tilted plug, front and rear BBs on the crankshaft, a new 2 piece

NVA designed for pacifier (pressure) fuel systems, a lightweight thrust

washer, and no web in the exhaust. The engine was bright tumble polished.

Internally, this was Fox’s first Schneurle ported engine. Some call

this the MK II Combat Special. The engine wasn’t very successful as

the crankshafts broke easily. This caused another Fox recall, but there

still seem to be a lot of these engines around. And sadly ladies and gentlemen,

this is the final descendant in the 35 Combat Special Line. |

|