In the April 1960 MAN, Fox advertised coming soon was a 59 Mark IV with a 19/32 dia. crankshaft running in 2 ball bearings, fully counterbalanced crankshaft, glass hard cylinder, machined aluminum piston with 3 rings….; “It costs twice as much –worth 10 times as much”. An airbrush illustration showed the engine. We never saw this engine, but saw a series of throttled front intake 59s.

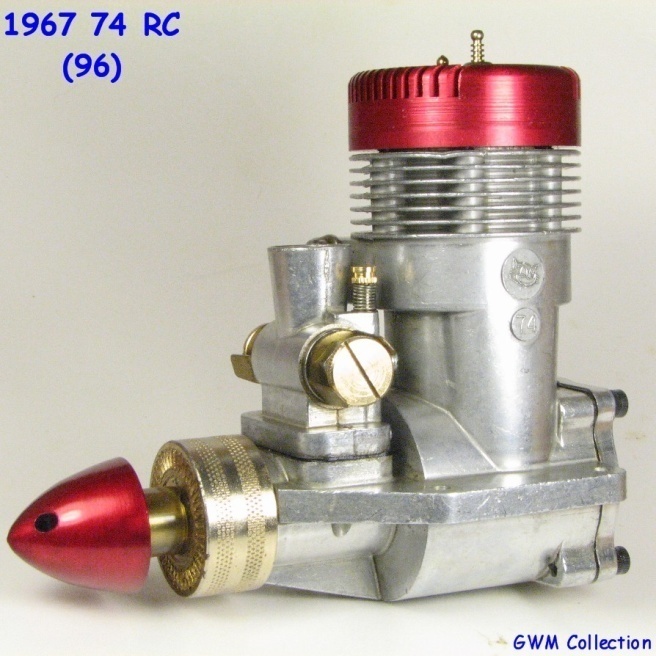

The 60 and 74 were never very popular. Scale fliers were building larger, heavier planes and in 1971, Fox stroked the 74 to produce the Fox 78 RC (113), 1.000 x 1.000 B&S. Maybe he had the crankshaft tooled up from the .90? Externally, it resembles the 74, but “78” is stamped on the bypass, the prop driver is a slightly different style gold anodized aluminum, there is a plain prop nut and washer, and a pronounced gap between the head and the case. The increased stroke required a thicker lip on the liner. Internally, the fabricated twin needle bearing rod was replaced with a more conventional bar stock aluminum rod.

The 78 was much more successful; scale fliers liked it. It went through various changes. The 3 jet carb was really excellent, but choked the engine too much (I think) and was too complicated to adjust for pilots who didn’t read instructions. Originally the twin plug head was thought to be required for reliable idle, many other manufacturers also used them. As throttle design evolved, the twin plugs weren’t found necessary. In fact on the Foxes, the plug on the bypass side sits square in the middle of the baffle slot in the head. You must use a SHORT plug as a long plug, especially with an idle bar, will definitely hit the piston baffle and tear it up, tear the plug up, or both and may leave bits and pieces churning around in the engine.

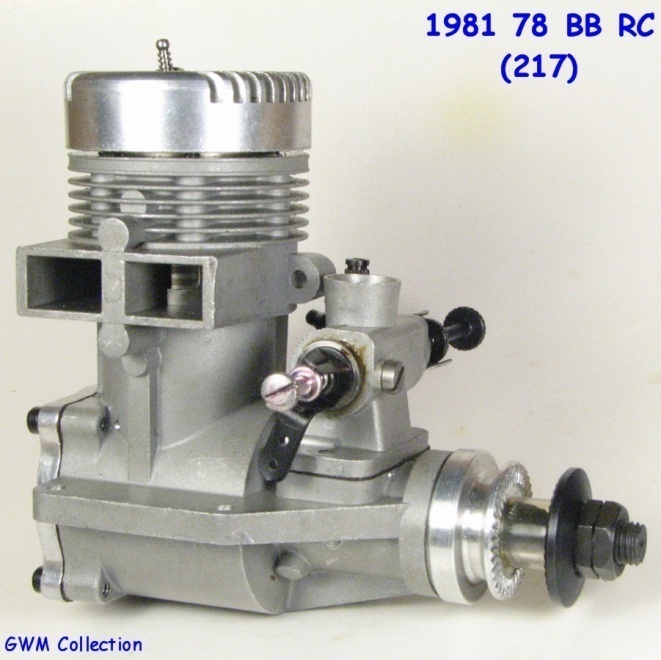

The Fox 78 RC case bypass was enlarged removing the Fox face and engraved.

Muffler bosses were added above and below the exhaust flange. Head was fitted with a single plug. And it was fitted with a new prop driver.

The last version of the 78 was produced in 1981 (217). By now it had a single tilted plug head, a heavier bronze bushed bar stock aluminum rod, a heavier bottom end on the crankcase*, and was fitted with the newly developed Fox MK X carburetor. This is the largest single cylinder engine Fox ever produced and is the final descendant in the 60RC Line.

*Note from Randy: I am not sure this is correct